Electronic corrosion, or electronic component corrosion, refers to the degradation or deterioration of electronic devices and components due to chemical reactions with the environment. Common causes include exposure to moisture, high humidity, corrosive gases, and airborne contaminants.

Electronic corrosion poses a significant threat as it can lead to malfunction or failure of electronic devices, affecting their performance, reliability, and lifespan. Corrosion-induced damage can result in increased maintenance costs, reduced productivity and data loss. It also affects the safety of critical electronic equipment in many applications, such as aerospace, automotive, and medical industries.

Electronic Corrosion

Electronic materials and devices corrode in the same ways as automobiles, bridges, and pipelines, but their typically small dimensions make them orders of magnitude more susceptible to corrosion failure. It occurs when metals and conductive materials in electronic circuits undergo oxidation or other corrosive processes.

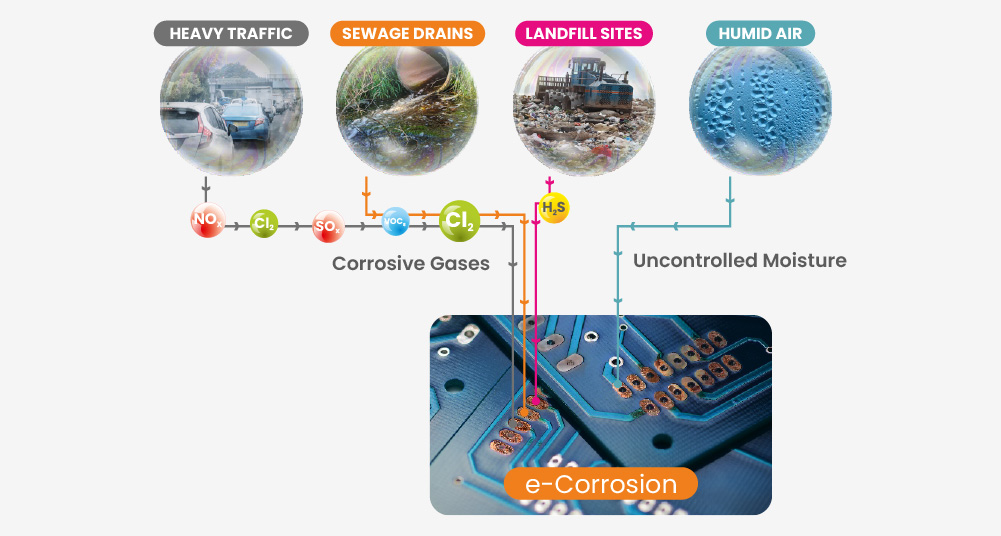

The exposure of electronic devices or components to environments where moisture and corrosive gases such as SOx, NOx, H2S, VOCs etc. cause corrosion on metallic components. This corrosion can lead to increased resistance, poor conductivity, short circuits, and ultimately, malfunction or failure of the affected electronic components.

|

Metal component corrosion in the electronic equipment occurs at different stages

|

|

|

Occurrence of Corrosion in Electronic Devices during

|

Different Stages of Manufacturing

|

|

Storage of Components and Assemblies

|

|

|

Assembly

|

|

|

Ship Transportation

|

|

|

Installation and Service of electrical equipment

|

|

|

Field Operations of the Equipment

|

|

Table: e-Corrosion occurs at various stages in electronic devices

Environmental Factors Cause Electronic Corrosion:

Moisture and Humidity: Exposure to moisture, such as rain, condensation, or high humidity levels, can accelerate electronic corrosion. Water acts as a catalyst, promoting chemical reactions that lead to the oxidation of metals and corrosion of electronic components.

Corrosive Gases: The presence of corrosive gases, such as sulphur oxides (SOx), chlorine (Cl2), or hydrogen sulphide, can contribute to electronic corrosion. These gases react with metals, forming corrosive compounds that degrade the electronic components over time.

Airborne Contaminants: Airborne contaminants, such as dust, dirt, or airborne particles, can exacerbate electronic corrosion. Contaminants can contain corrosive substances or provide a medium for moisture retention, accelerating the corrosion process.

Poor Storage Conditions: Inadequate storage conditions, such as storing electronics in damp or corrosive environments, can accelerate the corrosion process. Improper storage may expose microelectronic equipment, devices or components to moisture or other corrosive elements, causing damage over time. Also, it is important to note that these factors can interact and amplify each other’s effects, further accelerating the corrosion process. Proper design considerations, such as appropriate materials, protective coatings, and environmental controls, are crucial in mitigating the failures associated with electronic corrosion. Areas/Activities Produce Electronic Corrosion Agents

Coastal Areas: Electronics located near coastal regions are at a higher risk of corrosion due to the presence of high humidity in the air. The winds blowing from sea to land bring a lot of moisture with them leading to accelerated corrosion.

Industrial Facilities: Many industrial processes involve the use of chemicals or high temperatures that can lead to the production of corrosive gases. For example, metal refining, chemical manufacturing, and combustion processes in power plants can release corrosive gases such as sulphur dioxide (SO2), hydrogen sulphide (H2S), and nitrogen oxides (NOx). Also, processes such as welding, soldering, and cutting of metals produce gases like ozone (O3), nitrogen dioxide (NO2), and chlorine (Cl2), which can be corrosive to metals and other materials.

Automotive Vehicles: Vehicles, particularly those powered by internal combustion engines, emit corrosive gases as byproducts of fuel combustion. These gases include sulphur oxides (SOx), nitrogen oxides (NOx), carbon monoxide (CO), and volatile organic compounds (VOCs).

Landfill Sites and Sewage Drains: It releases corrosive gases, such as hydrogen sulphide and volatile organic compounds (VOCs) which react with moisture in the air, forming corrosive compounds. Image: e-Corrosion caused by corrosive gases and humidity present in the environment.

Image: e-Corrosion caused by corrosive gases and humidity present in the environment

Agricultural Activities: Agricultural practices involving the use of fertilisers, pesticides, and livestock farming can generate corrosive gases. For example, ammonia (NH3) released from animal waste and nitrogen-based fertilisers can corrode nearby structures and equipment. Electronic devices and components exposed to outdoor environments are particularly susceptible to corrosion.

Thus, it is important to consider these factors and their potential for generating corrosive gases. Proper management and mitigation strategies can help minimise the adverse effects of corrosive gases on infrastructure, equipment, and human health.Bry-Air SolutionBry-Air provides specialised equipment designed to ensure the longevity of electronic devices and components.

Bry-Air Solutions to Prevent Electronic Corrosion

Bry-Air Gas Phase Filtration System has emerged as an optimum solution for efficient removal of corrosive gases and airborne contaminants causing corrosion in electronic/electric circuits, bad odour, and harmful gases from the atmosphere housing critical systems, such as data centres, server rooms, research labs, diagnostic systems, and cold storage. Bry-Air Dehumidifiers are capable of maintaining low humidity levels, preventing moisture buildup and halting the corrosion process.

Bry-Air products are known to be the most reliable, constantly outperforming in output, services and value for money. Also, Bry-Air specializes in customising systems to specific customer and application needs across industries.